Turning one item into another can also be done with Disassembly (e.g. making leather patterns from a whole piece of unprocessed leather).

In AccountingSuite, the Disassembly is defined on the item card that is created for the primary product.

Maintain Item’s settings #

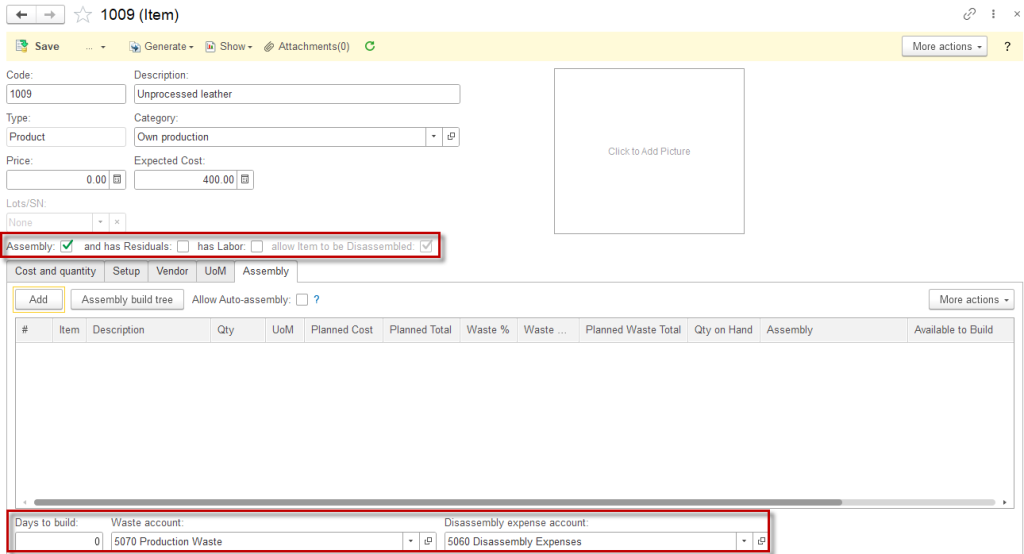

- On the item card, tick the Assembly box and allow item to be disassembled.

- Enter days to build

- Waste account and Disassembly expense account are pre-filled in accordance with Accounting settings, but they can be changed.

Create Disassembly #

- Navigate to Inventory → Assembly Build.

- Choose the Item to build from the drop-down menu. The list of raw materials needed will populate in the materials tab. Labor items appear in the labor tab.

- Choose the Location of the build. This is where the inventory of the completed items will be increased.

- Change the Build Date, Quantity, Unit of Measure if needed.

- If your assembled item will be assigned a lot or a serial number, click the Lots/Serial Number tab and assign them.

- Enter a Memo (optional).

- Save the document.

Please note:

- The Assembly Build will fail to post if there are not sufficient raw materials in stock.

- On an Assembly Build, individual items may be added, changed or removed to reflect the actual use at the time of manufacturing.

- An assembly item may contain another item that is an assembly on its Assembly build. There is no limit to how far deep you can nest assemblies but they must be built in order from the deepest nested assembly on up.

Accounting #

Recording an Disassembly build creates the following transactions in the General Journal:

- Debits: Inventory (of items made out of primary product). Inventory sum will include labor cost occured for the assembly

- Debits: Production waste cost account (for waste items)

- Credits: Inventory (of the primary product, which has been disassembled)

- Credits: Payroll Expense account (if “Has labor” box is ticked on the item card)

Status indicators #

In the Disassembly process, there are two statuses used to indicate the state of the disassembly tasks: Completed and Pending. These statuses help track whether the Disassembly of a finished product into its components is finalized or still in progress, ensuring accurate inventory management throughout the process.

- The Completed status means that the disassembly process has been fully executed. This indicates that the finished product has been successfully broken down into its individual components, and the inventory has been updated. The stock for the finished product is decreased, while the stock for each separated component is increased accordingly.

- The Pending status signifies that the disassembly process is still in progress or has not yet been finalized. This could occur if there are missing details, insufficient inventory, or if the process is awaiting approval. The inventory is not adjusted until the status changes to Completed, allowing for modifications or corrections to be made before finalizing the Disassembly.